Electric Arc Furnace (EAF) is a default phase in the process of making steel. Over years EAF has evolved dynamically and adopted efficient, competitive and sustainable methods in the process and the global output of steel from EAF is increasing. Many countries are on the verge of adapting EAF that cannot make iron by the traditional method, i.e., Blast Furnace route. One of the main reasons for the migration is because of diminishing supplies of coking coal and other raw materials.

In USA EAF steelmakers are known as mini mills and this industry is the largest recycler in the country, re-using more than 70 million tons of scrap steel annually. The core difference between the traditional integrated steel producers and the mini-mill producers is that EAFs cannot use taconite pellets because the pellets are only 65% iron and the iron contained in the pellet is not in a metallic form.

The focus on EAF mini mills made Mesabi Nugget operation to employ new technology through which it is producing the world’s first and only iron nuggets that are pure enough to supplant imported pig iron in mini-mill steel production. The process benefits the company with overall lower capital costs and lower operating costs compared to traditional iron making and the mini-mill steel production is 30% more energy efficient than traditional blast furnaces that make steel from taconite pellets.

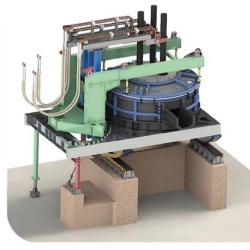

Siemens Simetal EAF Quantum furnace has combined proven shaft furnace technology elements with new processes to reduce carbon dioxide emissions and saving energy and costs. This is flat-bath operation that considerably reduces the strain on the furnace and lessens the repercussions for the power grid. Siemens has developed Simetal EAF FAST DRI, an electric arc furnace specifically for use with direct reduced iron that shortens tap-to-tap times and reduces specific energy consumption and results in the productivity of a 150-ton furnace can be increased by around 15%.

Evolution of Technologies in EAF design to reduce tap-to-tap times is in wide range. They are:

- Ultra High Power design, with high secondary voltages and longer arc

- High current conducting electrode arms in copper-clad box design

- State of the art electrode control system

- Extensive use of alternative energy sources

- Better energy and thermal balance inside the furnace because of multiunit injection

- High yield of alloy additives and high ladle refractory life thanks to EBT slag-free tapping

- More heat input in cold EBT area thanks to special design of EBT-burner system

- Heavy construction design to sustain hard working conditions that allows very fast movements and safe operations

- High flexibility and high efficiency of furnace operation with closed slag door application

- Easy maintenance operation for special design like roof lifting system, furnace locking system

- Split-shell design

- Copper or combi-panels with high-speed cooling water flow

- Continuous DRI/HBI feeding systems

- Additional chemical energy based on carbon, fuel and oxygen is used as substitute of electric power

- SIM-ARC electrode regulation design

- Hot heel practice

- Fast scrap charging

- Scrap yard flexibility

The EAF process solely depended on Electrical power till the chemical energies turned as supplementary to reduce the conversion cost through improved EAF productivity. However, the efficient management of electrical and chemical energy is by combining efficient dynamic control of the electric arc with a balanced injection of oxygen and carbon in order to increase EAF productivity. EAF plants often use a mix of DRI and recycled steel feeds and carbon based materials as slag foaming agents and as carburizers. As per the requirements on the reduction of energy consumption and greenhouse gas emissions, traditional anthracite and metallurgical coke are replaced with carbon based materials and now the alternative carbon sources like end of life rubber tyres and recycled plastics are partially replacing the conventional carbon materials.

EAF with Rubber Tyres and Plastics

A study conducted by OneSteel Sydney Steel Mill in collaboration with UNSW in laboratory testing on use of rubber tyres in EAF steelmaking for foamy slag optimization has developed and commercialized an engineering system through plant trials for EAFs to inject blends of rubber from end of life tyres and coke into EAF as slag foaming agents.

The method resulted benefits like, increase in volume and foaminess of the slag include improved electrical energy efficiency due to a longer arc and improved heat transfer from the arc to the steel, as well as decreased heat loss through the slag and sidewalls. While, EAF steelmakers using Polymer Injection Technology can also expect to see improvements in yield, inject oxygen consumption, refractory and electrode consumption, and injection system wear. The Rubber Injection Technology (PIT) has become a standard process at OneSteel’s Sydney and Laverton EAF Steel Mills and has achieved significant milestones with

- 40, 720 heats tapped with rubber injection

- 13,721 tonnes of coke reduced due – substituted and reduction in injection due to FeO control and consistent sizing

- 1,128,486 equivalent passenger tyres used

The resulted green steel from old rubber tyres and plastics produces no waste or toxic fumes. Prof. Veena Sahajwalla, Director of SMaRT at the UNSW said that, “The really exciting side benefit was that the recycled scrap rubber or plastic material produced a more stable foamy slag in EAF compared to using coke only, this greatly improves the steel furnace’s energy efficiency.” She also hypothesized that if recycled rubber or plastic was subjected to rapid and very high temperatures it would change into the carbon material that joins with molten iron to make up steel along with clean gases such as hydrogen and carbon monoxide.

OneSteel’s commercial furnaces are incorporated with this technology in two of its Australian operations as a standard practice. As of March 2012, the technology has replaced almost 15,000 tonnes of coal with more than one million car tyres. This has reduced many millions of KWh hours of energy each year while increasing furnace productivity and producing more steel from the same amount of ferrous scrap.