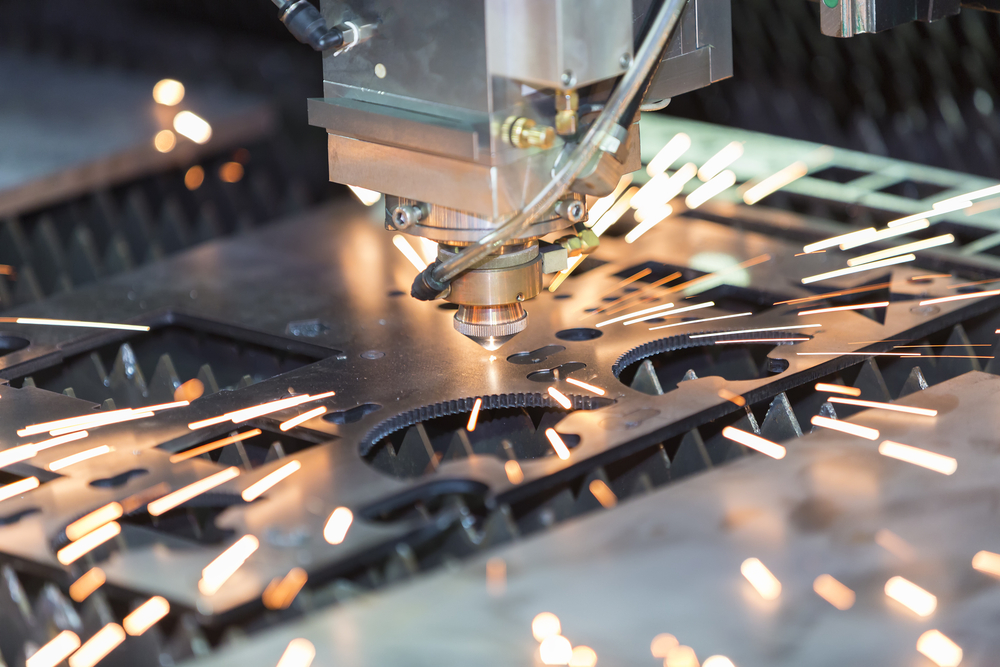

Opting to operate a laser cutter in-house for parts fabrication and other tasks can be a significant time and money saver. Thanks to advances in technology, modern cutting machines are easier to use, more efficient, and capable of making more detailed and precise cuts than ever before, but before you invest in one for your steel plant, there are some important points to consider.

The Space Available for the Cutter

Even if you select a smaller laser machine for your business, there are some space issues that you need to consider to ensure that the machine works efficiently and remains in good working condition over time. For example, you need to ensure ample clearance above and around the machine to allow for maintenance technicians to work on the machines when necessary. In addition, most laser cutters use external air water chillers, which not only require space themselves, but they also create heat. Without enough space between these chillers and other equipment, you could run into problems with operating both the laser and other equipment.

Also, keep in mind that the laser cutter will create dust and slugs that need to be collected and routed through duct work to a blower and exterior exhaust. This is especially important in a steel plant, where combustible dust is already a significant concern. In addition, OSHA has strict standards for ventilation in steel-cutting environments, particularly when working with potentially toxic materials. Although some models of cutters include a slug drum to collect dust and shavings, this adds to the space needed for the machine, which must be accounted for in addition to the ventilation of the machine.

Power

Depending on the type of steel you plan to cut or engrave, you will need a machine with adequate power. For cutting steel, as well as other metals like brass, aluminum, and titanium, you need a machine with at least 500 watts of power. Lower wattage machines are generally reserved for cutting thinner materials.

However, with more power in the machine comes more power consumption. As you evaluate machines, carefully review each model’s power consumption estimates and how that will contribute to the overall cost of ownership and affect the bottom line of your plant or workshop.

Climate Control

The climate control required for the laser cutter can also contribute to the power consumption and cost of ownership of the machine, and play a role in where you locate the machine. Ideally, laser cutters should be kept in climate-controlled environments with low humidity, as when the temperature gets too high (i.e., above 95 to 100 degrees) the laser will not work consistently. In addition, lasers can become nonfunctional if the temperature of the chiller is allowed to reach the dew point of the room or lower. Therefore, it’s important to consider where the machine will be located and how the temperature and humidity will be managed to ensure optimum operational efficiency and avoid unnecessary and costly shutdowns.

Maintenance Issues

As with any machine, laser cutters need to be maintained. Fluids need to be changed and filters replaced; lasers need to be inspected, recalibrated, and realigned; and other important maintenance tasks must be completed to ensure the machine works as it should.

In many cases, original equipment manufacturers include standard maintenance in the purchase contract, but it’s important that you confirm that maintenance is available, and that if it is not offered by the OEM, that you have access to a trained and qualified maintenance provider who can perform those tasks for you.

Ease of Use

Finally, before you purchase a machine, it’s vital to make sure that you have individuals on staff who actually know how to use it, or can easily learn. It seems that would be an obvious priority, but it isn’t always. Laser cutting is different than other forms of steel cutting, and requires a different set of skills and a different approach than what your team may be trained and experienced with. In addition, while most lasers in plant applications are Class 1, meaning that there is no risk of radiation and therefore a dedicated safety officer is not required by OSHA. Many experts and OEM’s of laser cutters recommend designating one or more employees as the “safety officer” to become an expert in the safe operation of the lasers and the proper maintenance and function of the machine. This is in addition to meeting all other requirements for safety in the steel cutting operation.

Again, adding a laser cutter to your array of steel-cutting tools can help your business become more productive and efficient, while also potentially opening up new product lines. However, before you invest in a machine, consider these factors to ensure you make the right choice for your needs and capabilities.